Awọn Irinṣẹ Ige Didara to gaju Awọn imọran milling Carbide APMT1604PDER 202 fun gige gige.

Alaye ipilẹ

Carbide APMT PVD Ti a bo ifibọ ti wa ni commonly lo fun indexable square ejika opin milling cutters ati oju milling cutters.Awọn ifibọ APMT wa pẹlu IC ti konge-itọkasi, fifọ chirún didimu rere.Wọn ni eti gige didasilẹ ati honed ati igun iderun 11°.Wọn wa pẹlu awọn ihò skru ti a ṣẹda ni ibamu pẹlu ISO.Ni deede, a wo bi pẹlu awọn egbegbe gige 2.Sibẹsibẹ, wọn ni awọn egbegbe gige 4 gangan.nigba ti won ti wa ni sori ẹrọ lori 90 ° indexable milling cutters ati awọn mejeji egbegbe di ṣigọgọ, won le wa ni fi sori ẹrọ lori 75 ° indexable milling cutters  ati ki o tẹsiwaju miiran milling ohun elo pẹlu awọn miiran meji egbegbe.APMT yoo jẹ nla kan wun fun opin awọn olumulo, niwon o. le significantly mu ise sise.Agbara Ipese:100000 Nkan/Awọn nkan fun oṣu A tun pese awọn ifibọ titan carbide miiran iru.

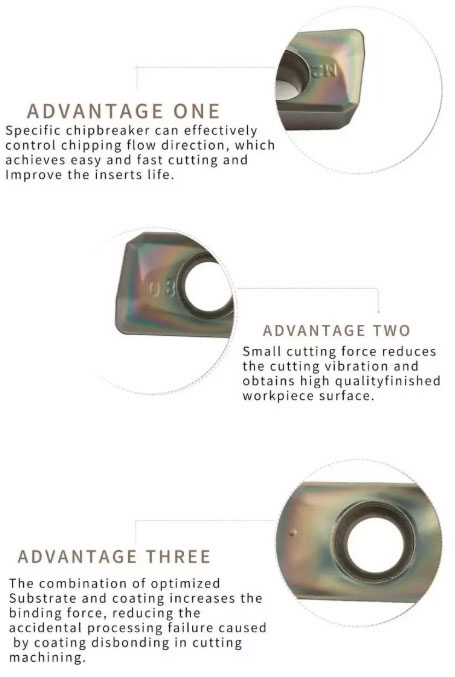

Awọn anfani

1. Idaabobo yiya ti o dara, agbara fifun giga, agbara ifunmọ ti o lagbara, iṣeduro ooru ti o dara julọ, ipa ti o lagbara ati lile lile.

2. Gigun iṣẹ igbesi aye ati rọrun si apejọ, ko si kiraki tabi chipping

3. Awọn apẹẹrẹ ọfẹ wa.

4. Awọn ibere kekere jẹ itẹwọgba fun ifijiṣẹ yarayara ati lati ṣe iranlọwọ fun ọ lati dinku iye owo ọja.

Awọn ẹya ara ẹrọ

1. Awọn ohun elo ti o ni wiwọ ti o ga julọ ti a ṣe apẹrẹ fun sisẹ ohun elo irin alagbara

2. Iwọn pipe ati iṣedede giga

3. Eto iṣakoso didara to muna lati ṣe iṣeduro didara didara

4. Ilẹ-itọka ati didan, ipa gige pipe

5. Iboju PVD ṣe idaniloju igbesi aye ọpa to gun.6.Gbogbo awọn ohun elo aise ni idanwo ni awọn ofin ti iwuwo, lile ati TRS ṣaaju lilo.

Ohun elo

Ohun elo akọkọ:Fun processing erogba irin, simẹnti irin, irin alagbara, irin

Ile-iṣẹ ohun elo:Yiyi CNC ati milling tungsten carbide irinṣẹ awọn ọja awọn ifibọ ti wa ni lilo pupọ ni: Ile-iṣẹ iṣelọpọ adaṣe, ile-iṣẹ iṣelọpọ mimu, ile-iṣẹ ọkọ ofurufu, ile-iṣẹ olugbeja, ile-iṣẹ iṣelọpọ eru ati ọpọlọpọ awọn aaye miiran.

a le ṣe agbejade ọpọlọpọ awọn oriṣi tungsten carbide gige awọn irinṣẹ fi sii ni ibamu si awọn iyaworan ti adani ti o yatọ.

a le pese awọn solusan atilẹyin gbogbogbo fun aaye ẹrọ ẹrọ.

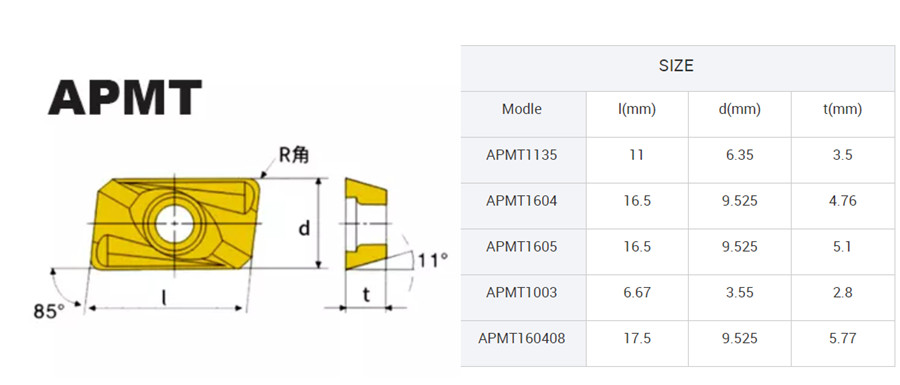

Awọn pato ọja

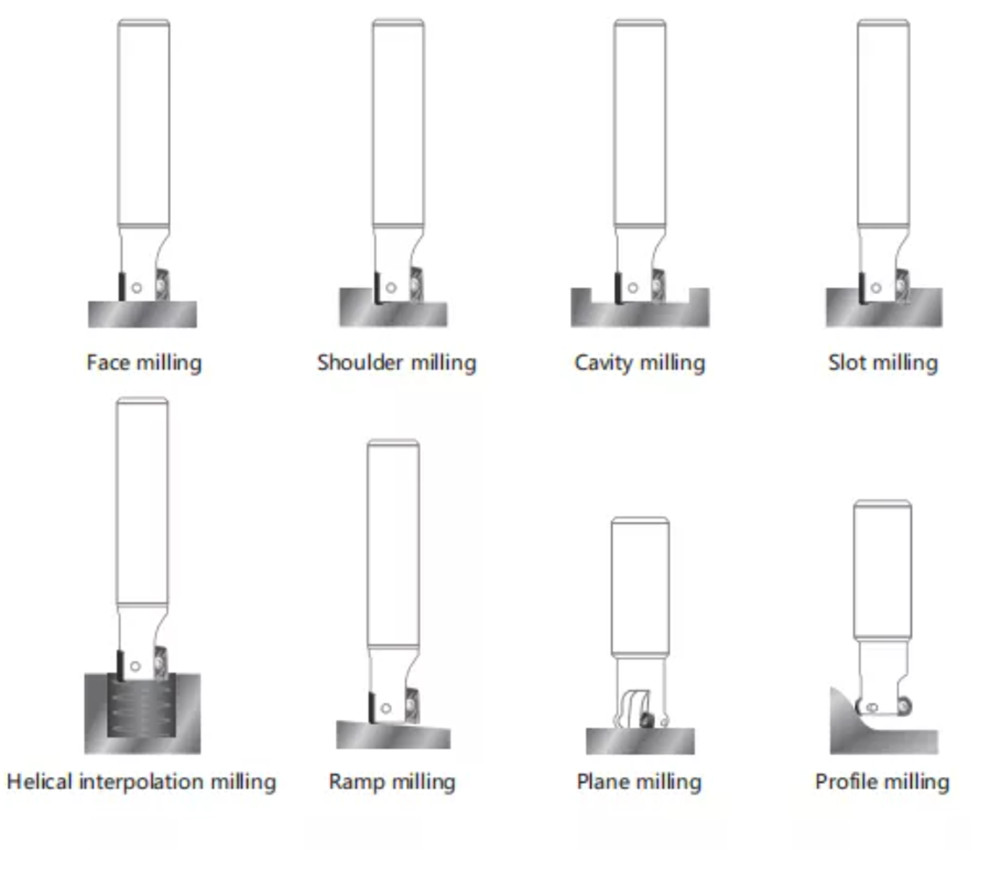

Boya o nilo kan gbogbo milling tabi eru milling ifibọ fun oju milling, ejika milling, Iho milling, profaili milling, tabi rampu milling, tabi paapa milling ti o ga awọn ibeere ti dada smoothness, Wa ẹlẹrọ le tan rẹ oniru sinu kan milling fi sii ni o kan ọjọ.

Aso Ifihan

Awọn iwe-ẹri

Awọn ohun elo iṣelọpọ

Awọn ohun elo QC